Microfluidics System Development: Challenges and Considerations

Developing fluid-based products can be challenging, given the different elements and requirements that must be considered and accounted for. Microfluidics system development raises the bar even higher, as the reduced fluid volume scale can change the physics of fluid flow, add complexity to the fluid circuit design, and limit manufacturing options. Key requirements for efficient microfluidic system development include:

- An experienced, multi-disciplinary development team

- A proven product development process

- Expertise with fluid-related design and engineering tools

- Deep manufacturing experience

- Regulatory expertise

Manta has deep expertise in developing traditional tube-and-fitting-based fluidic circuits and chip-based microfluidics systems for research, diagnostic, and treatment applications. If your product requires precise fluid control and delivery, we can help you navigate critical system architecture decisions, streamline the design process, and avoid potential development pitfalls.

Manta Product Development (Manta) is an award-winning product development firm located in Cambridge, MA. Our product development process delivers innovative solutions and competitive value to companies in the medical device, analytical/scientific instrument, robotics, consumer electronics, and industrial markets.

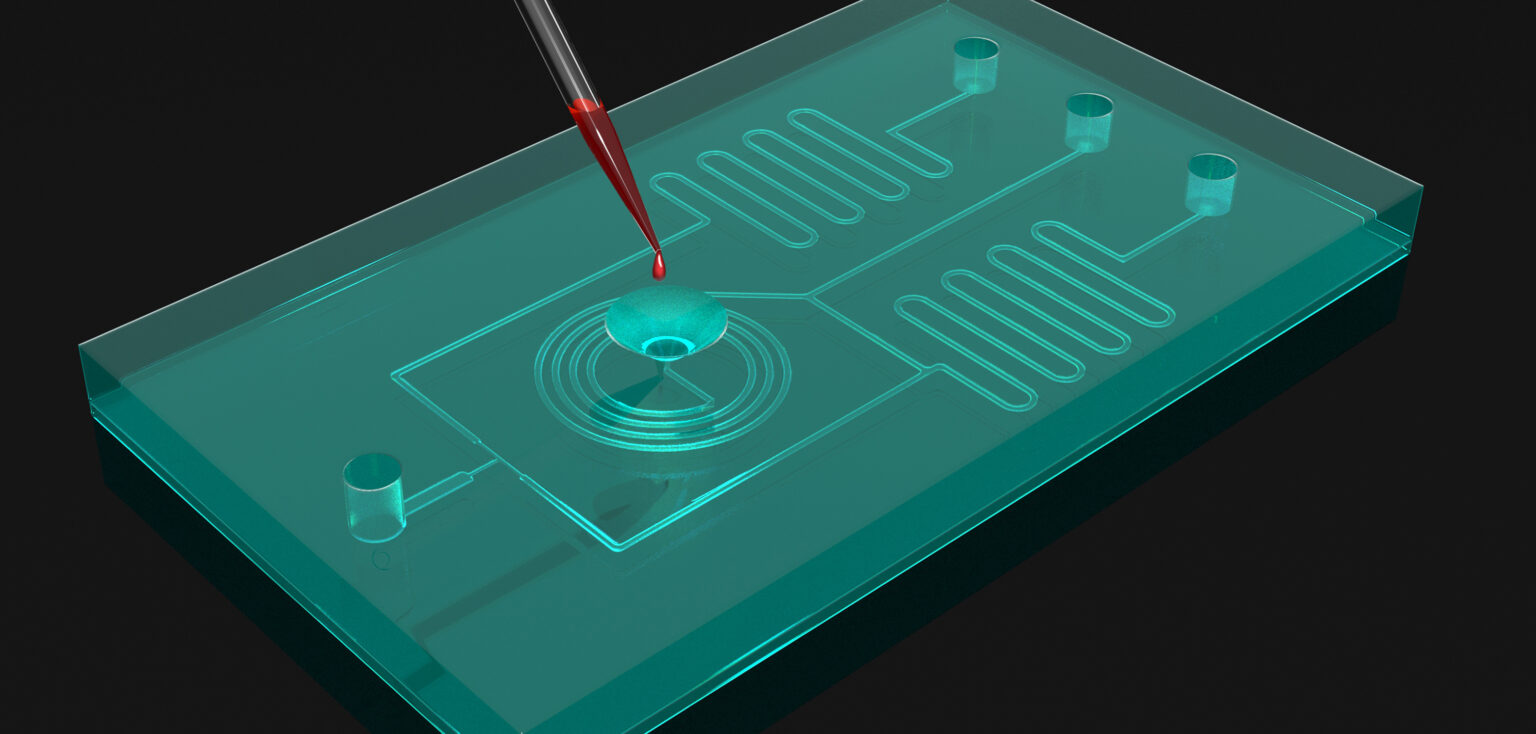

Microfluidics Chip

Experienced Multi-disciplinary Development Team:

Critical skills/experience required for fluidic-based product development include a deep knowledge of fluid dynamic principles and significant expertise with fluid circuit microfluidic chip design, prototyping, and manufacturing. The fluid circuit can be characterized by the scale of the liquid volume in the system, and each has its own fluid dynamic and manufacturing-related aspects:

Traditional fluid systems typically comprise tubing and off-the-shelf fittings and processing components, which provide rapid prototyping options and often a direct transition from prototype to production. However, these systems do not provide the volume efficiency, control, or accuracy that microfluidic systems offer. Additionally, biological and chemical applications often benefit from smaller-scale fluidic architecture due to differences in fluid and thermodynamics. “Microfluidics” refers to the science and manufacturing of fluid systems that include micro-channels, chambers, and tunnels that manage fluid flow interactions. These systems include microfluidic chips comprising one or more layers containing a pattern of microchannels that can be machined, molded, engraved, or etched. In regular usage, the term “microfluidics” can encompass two fluidic scales - millifluidics and microfluidics, each with different design considerations:

Millifluidic systems are significantly smaller in scale than traditional systems - fluid volume is between a microliter and a milliliter, with chip channel features around 1 mm in size. Millifluidics manipulate smaller volumes of liquid than traditional systems, allowing for easier prototyping and fabrication than smaller-scale microfluidic systems since parts can be made using traditional CNC machining and other “common” fabrication techniques. This technology has many applications, including biotechnology, precision liquid handling, pharmaceutical engineering, patient diagnostics, and research. Millifluidics provides efficiencies over traditional fluidics when diagnosing small biological samples and using expensive reagents. In addition, millifluidics can simulate human tissue's mechanical and fluidic environment, making this technology a good match for drug testing and disease modeling.

Microfluidic systems have fluid volumes on the microliter scale or less, with physical chip features finer than 0.1 mm. These systems accurately manipulate very small fluid volumes (including single-cell or even single-molecule manipulation) and require a more specialized design, development, and manufacturing process due to these small feature sizes. There are also non-channel-based microfluidic technologies such as lateral flow/paper-based technologies (as seen in at-home COVID tests), digital microfluidics, and EWOD (electrowetting-on-dielectric) systems.

Microfluidic chips generally have multiple external interfaces beyond simple liquid inputs and outputs. Therefore, fluidic system design often requires a broad multi-disciplinary development team that includes mechanical, electrical, software, and optical engineers, industrial designers, human factors/usability engineers, regulatory specialists, and quality control resources.

Manta’s team includes MIT engineers with decades of experience in fluid dynamics, precision fluid delivery, and fluid circuit/chip design, prototyping, and manufacturing. Manta’s industrial designers, ergonomic specialists, and usability engineers focus on making the chip-device interfaces and overall device operation simple and intuitive, which is critical to assay execution and preservation of high-value samples. Manta also has a wealth of experience in precision motion control, thermal management, and optical detection technologies, which are often required in microfluidic devices and systems.

Regulatory team members ensure that the microfluidic device design complies with FDA and other regulatory agency standards, and quality team members focus on the repeatability and reliability of the instrument and chip throughout the product life cycle.

A Proven Microfluidics System Development Process

In addition to a strong, multi-disciplinary team, microfluidic device development requires an efficient and proven development process. This is particularly true for devices and applications under FDA/regulatory agency control, but is equally important for research-targeted devices and systems. A robust design process includes research, system architecture conceptualization, usability engineering, risk mitigation strategies, feasibility testing, design development for manufacturing, and manufacturing transfer and scale-up.

The development process starts with a feasibility/concept development phase. In this phase, key requirements (assay-related, functional, user, marketing, regulatory, etc.) are identified and captured for follow-on design development and verification/validation activities. User research is conducted to identify device workflows, existing pain points/opportunities, and associated user needs. Feasibility design and prototyping are undertaken to prove and derisk key technical and performance-related requirements. Product architecture solutions, including machine/chip interfaces (mechanical, fluidic, electrical, etc.) and the target fluidic “scale,” are explored to identify the optimal product configuration. Chip manufacturing strategies are identified and vetted to keep within the selected fluidic scale (traditional, microfluidic, nanofluidic). Applicable regulatory pathways and standards are identified, and a regulatory plan & strategy is developed.

Once the overall device requirements are defined, technical feasibility is successfully demonstrated, and the product architecture is selected, the project is ready to move into the detail design / DFMA phase. Detailed mechanical/fluidic, industrial design/usability, electrical, software, and optical development activities are undertaken, typically involving design-prototype-testing iterations. Target manufacturing partners are selected and engaged for design for manufacture and assembly (DFMA) feedback and input that is incorporated into the chip and device designs. Regulatory activities are conducted throughout the phase, including design controls, risk management (dFMEA’s and Hazards Analysis), and usability engineering (expert reviews / formative studies). A verification and validation (V&V) plan is written, and corresponding test plans/protocols are developed. The phase outputs are proven, thoroughly documented chip and instrument designs ready for manufacturing transfer.

The manufacturing transfer phase includes chip tooling cycles, manufacturing fixture development, pilot builds, and quality control activities. Initial production units are used for verification and validation testing, formal summative usability testing, and clinical trials (if required). Regulatory certification testing is undertaken, and regulatory submissions/approvals are obtained.

Manta’s product development process has been honed and optimized over our 30-year history of successful product development programs in the fluidics/medical/analytical instrumentation fields. We leverage this experience throughout the development process to minimize development time while avoiding common pitfalls.

Expertise with Microfluidics Design and Engineering Tools

In addition to a targeted development process, effective microfluidic system development requires a variety of specific tools and equipment. Manta possesses extensive experience utilizing a wide range of specialized development tools/equipment to optimize microfluidic system design. Computational Fluid Dynamic (CFD) software is used to quickly model, simulate, and optimize fluid flow through the fluidic circuit flow channels, reducing design iterations and overall development timelines. 3D CAD Software is used to precisely define and control microfluidic chip and instrument geometry, tolerances, and features, ensuring a smooth transition from prototyping to production, and facilitating manufacturing quality control over the product life cycle. Manta also has a wide range of microfluidic chip prototype fabrication equipment, including high-precision CNC machining and 3D printing technologies, an analytical lab, and associated equipment for fluidic circuit-related testing, significantly reducing the design-prototype-test cycle time.

Manta’s quality management system (QMS) is utilized for microfluidic applications that require FDA submission and approval, including patient diagnostic and treatment-related devices and systems. The QMS includes SOPs and procedures for design control, risk management, and verification/validation (V&V) activities in accordance with ISO 13485 and 14971 standards. Finally, Manta is well-versed in the usability engineering requirements of ISO 62366, which governs the usability of a medical device in terms of safety.

Deep Manufacturing Experience:

Successful microfluidic system development requires a complete understanding of chip manufacturing processes, production material selection, packaging design, sterilization (if required), and manufacturing transfer. The scale of the fluid volume dictates fluid circuit manufacturing strategies and options:

Traditional or macro-scale fluidic systems use individual fittings and tubing to create the fluidic circuit, and custom parts are often not required. This method allows for quick changes during prototyping, eliminating the need to fabricate an entirely new part to change the fluid path, and there is often no difference in the fluidic layout and components between prototype and production. Using multiple discrete components and/or the labor to assemble tubing-based systems can mean a higher final CoGS (cost of goods sold) price, which can become prohibitive if some or all of the fluidics path is consumable. Using larger fluid volumes requires more reagent volume and thus has a higher reagent cost.

Millifluidic manifolds (AKA chips) are manufactured via machining or molding and replace some or all the tubing and fittings of macro-scale fluidics with channels in plastic, elastomeric, paper, ceramic/glass, or even metal substrates. These channel layers can be sealed with a thin film, and/or multiple channel layers can be laminated together like multi-layer electronic PCBs. More engineering effort is involved in creating an integrated fluidic manifold, and changes to a prototype often require remaking the entire manifold. The millifluidics channels are large enough to be CNC machined or printed on specialty 3D printers, resulting in cheaper, relatively low-lead time prototypes and more extensive material choices.

Microfluidics systems using channels less than 100 µm [0.004”] require specialized prototype and production methods. The channels are created in chips made from glass, silicon, plastic, or 3D-printed resins. Channels are fabricated using various methods, including molding, thermoforming, etching, and photolithography techniques borrowed from semiconductor manufacturing.

Manta has extensive experience in the manufacturing of both traditional fluidic circuits and microfluidic chips. Manta’s development teams stay intimately involved throughout the manufacturing transfer and production ramp-up process to ensure the design intent is upheld and quality/repeatability/reliability are maintained.

Microfluidics Regulatory Expertise:

Microfluidic devices are used in an increasingly wide variety of applications, including life science research, drug discovery, environmental monitoring, clinical diagnostics, and patient therapy. The regulatory requirements and governing bodies for microfluidic devices and systems are dictated by various factors, including their intended use, safety/risk classification, complexity level, and target markets. In the United States, microfluidic devices intended for clinical diagnostics or therapeutic/patient treatment applications are regulated by the Food and Drug Administration (FDA) and must be developed and manufactured in accordance with FDA guidelines and standards.

As discussed above, it is important to identify the regulatory pathway(s) and develop an associated regulatory strategy for a microfluidic device in the initial concept/feasibility phase of the development process, and to incorporate regulatory compliance activities throughout the entire product lifecycle. This includes design controls, risk management, usability engineering, good manufacturing practices, and, if applicable, biocompatibility, sterilization, and clinical trials.

Summary

Developing a fluid-based product can be complicated and full of potential pitfalls. Critical factors for success include an experienced multi-disciplinary team, a strong development process, and the right tools. Manta has been helping our clients in the medical, analytical, scientific, and industrial spaces with fluidic/microfluidic development support for 30 years.

Please reach out to us if you would like more information or to discuss a potential project, either through our website, www.mantadesign.com, or contact Rich Miller, VP of Engineering, rich@mantadesign.com

MANTA

Our experienced team of researchers, designers, and engineers can help you create a standout user experience, elegant enclosures, and innovative solutions for your products - no matter the industry. Get started now.