Manta's turnkey product development services expertly develop product concepts into production-ready solutions. Our team works closely with manufacturing partners throughout the development process to ensure your product is completed on time and achieves its cost, performance, and reliability goals.

Our Process

Product Development

With over 25 years of product development experience, we are experts at evaluating technologies, identifying opportunities, innovating, managing development, and rapidly transitioning to effective production solutions. We meet user needs, solve complex ergonomic and engineering issues, and communicate compelling brand stories to targeted markets:

Electrical engineering

Mechanical engineering

Optics, acoustics, thermal, and fluid dynamics

Software development

Design verification

Design for Manufacture and Assembly (DFMA)

Failure Modes and Effects Analysis (FMEA)

Finite Element Analysis (FEA)

FDA design control process

Prototype fabrication, assembly, and testing

Regulatory agency design (UL, CSA, CE, IEC)

Risk analysis and mitigation

Tolerance analysis

3D CAD solid modeling and surfacing

Design Assurance

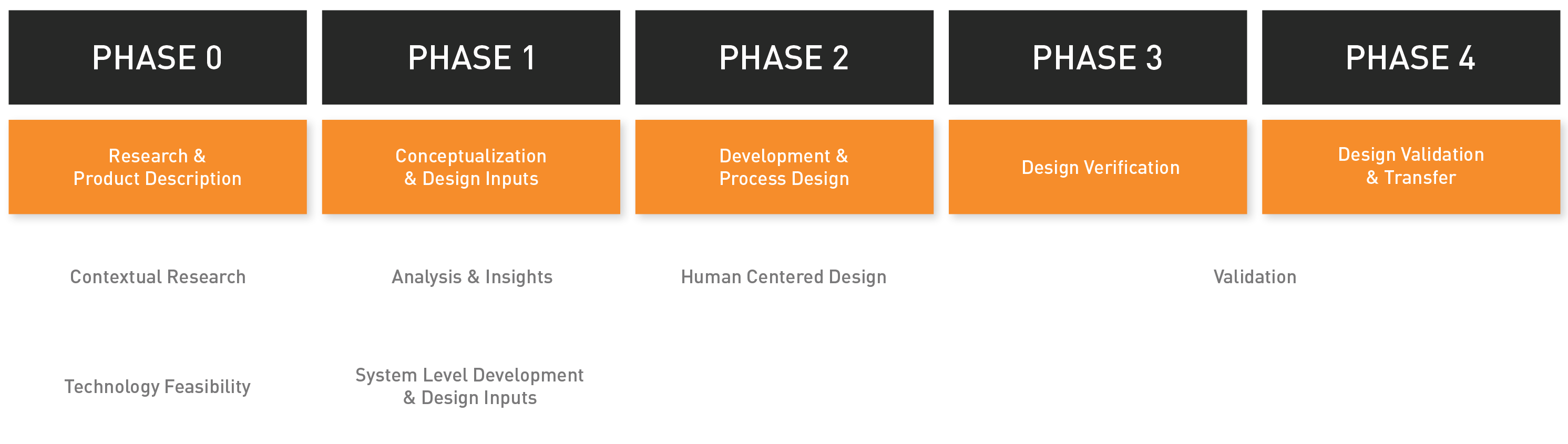

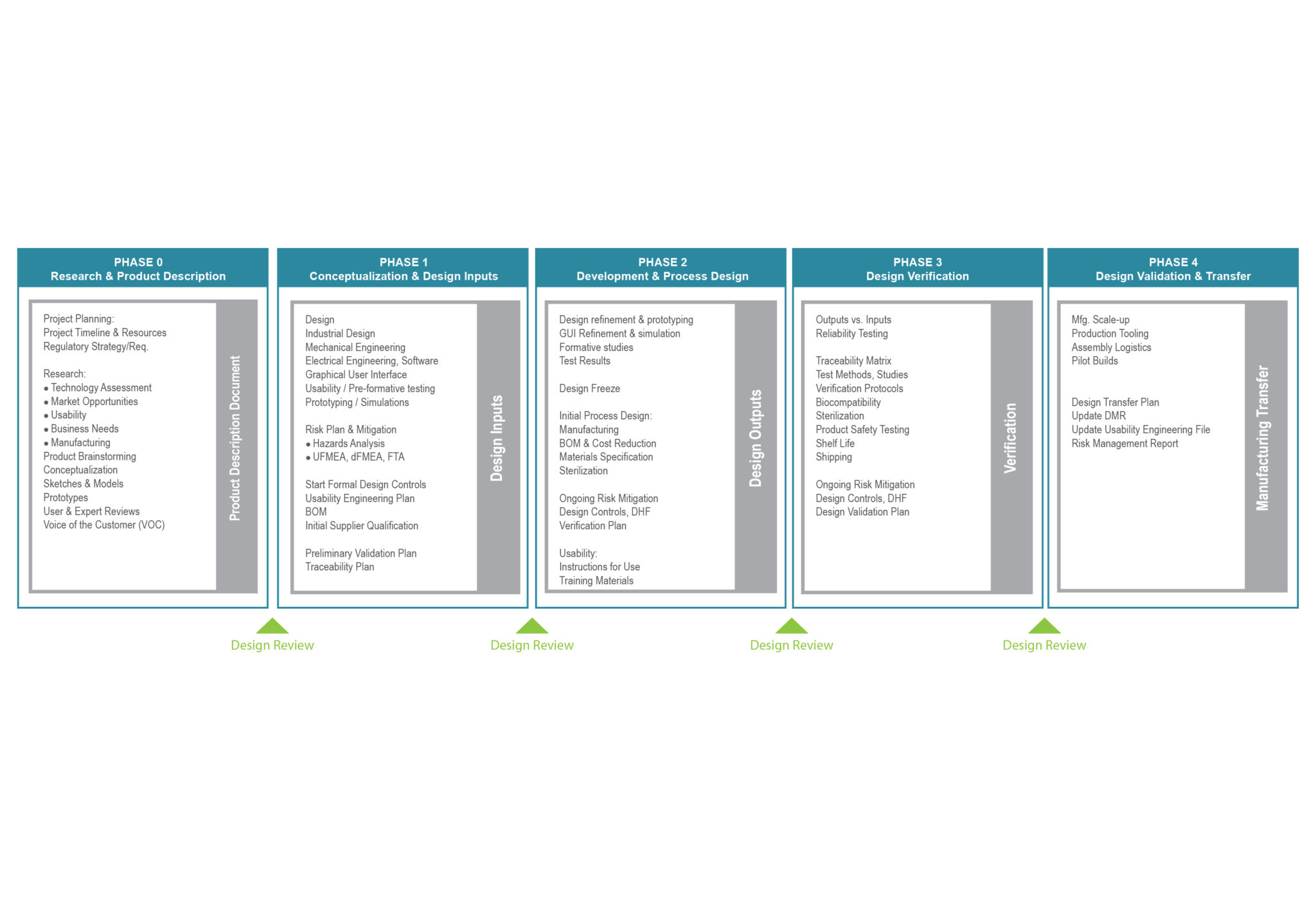

Manta's development methodology process integrates innovation activities in the context of risk mitigation to ensure they are directly aligned with your business plans and objectives.

Our product development process fully complies with the design assurance guidelines outlined in FDA 21 CFR 820, ISO 13485, and adheres to the FDA and European human factors guidelines including HE 75 and ISO 62366, and incorporates risk management per ISO 14971. We integrate specific design assurance activities including:

Documentation control

Traceability

Verification and validation

Risk management

Usability and human factors

Design Inputs/Outputs

Design History File (DHF)

Device Master Record

HARA (Hazards Analysis)

Failure Mode and Effects Analysis (uFMEA, dFMEA, pFMEA)

Manufacturing Transfer

Manta's extensive manufacturing experience ensures a smooth transition of your product development into production. Our comprehensive network of domestic and overseas vendors, suppliers, and contract manufacturers give you the highest quality, most cost-effective manufacturing services in the field.

Our manufacturing team oversees part-tooling cycles and first article inspection activities, and manages your product's reliability, regulatory, and qualification testing. Not only do we create complete documentation packages for part procurement, part inspection, and quality assurance/control purposes, we also assist your manufacturing groups with tooling and fixture design and assembly training.

Our manufacturing transfer services include:

Contract manufacturer management/liaison

Engineering change and design change control orders

Manufacturing fixture and jig design

Part inspection and qualification

Pilot production support

Production documentation packages

Production part and tooling quotations

Vendor sourcing and qualification

Regulatory testing

Reliability testing

Tooling cycle management

Quality assurance and quality control activities

Engage with Manta.

Let’s discuss your product development needs and propose a project plan.