How To Develop Successful Wearable Devices: Challenges and Considerations

From 2014 to 2018, the use of wearable devices increased from 9% to 33%, according to a study by Accenture. Forbes predicts that wearable devices will be a $27 billion industry by 2022. But many companies looking to enter this market are unsure of how to develop wearables successfully.

Equipped with sensors, microprocessors, and an internet connection, modern wearables are in fact powerful wearable computers. Although the underlying system architecture of wearable technology appears simple, the tradeoffs involved in building it are complex. As we see more companies look to make wearables, we also see them encountering unexpected challenges.

This is even more true for companies pursuing narrow applications for their technology. While fitness trackers were the first to go mainstream, more firms are specifically developing wearable technology for healthcare. With better sensor technology, we can gather real-time data on valuable vitals like blood pressure, glucose and ECG measurements. However, as medical devices, these types of wearables need to meet specific production, efficacy, and safety standards.

Whether they have medical applications or not, wearables are a unique category of technology. Developing them successfully requires expertise and strong partnerships. We’ve distilled our experience into a trusted development process specific to wearable devices.

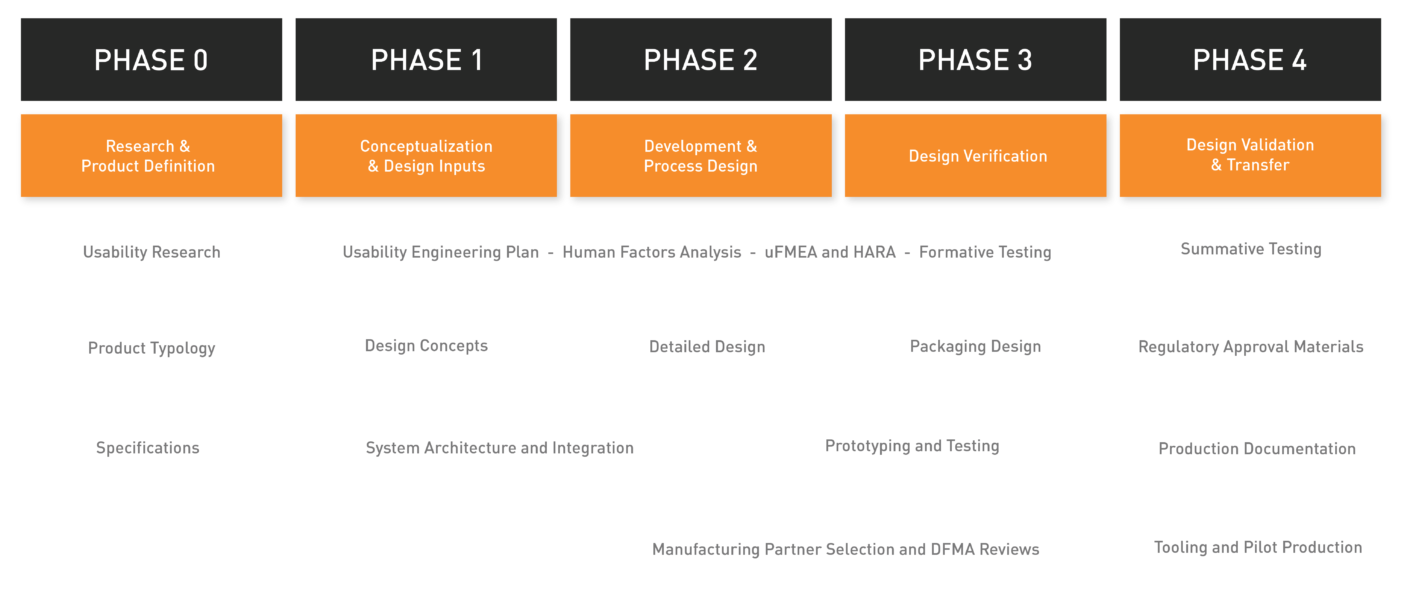

How do we develop wearable devices?

We follow a design-thinking process to drive the development of wearable devices. However, the nature of wearable devices poses unique challenges. These revolve around its comfort, its accuracy, and its power use. The choices made about the components and their integration within a form factor determines the success of the device. These choices drive how convenient, efficient, and effective the device is.

What are unique considerations when developing wearables?

Delivering a Highly Valuable and Usable Product

Frank McGillin, Chief Commercial Officer of Neurometrix, led the creation and launch of the Quell® consumer digital health brand. His number one piece of advice for wearable companies: “Make sure you’re designing your wearable for your intended user.”

The sustained success of a wearable hinges on how much customers enjoy using it. Since these devices are often worn 24/7, good user experience is essential. With different user research methods, you can dig into your customers’ needs and craft a product that integrates into their daily lives and habits.

As McGillin says, “Someone may be used to brushing their teeth every morning, but they may not be used to strapping a band on their leg.” By getting out and talking to prospective users, you can leverage insight into their desires and behaviors to deliver a product they can build a habit around. With the Quell®, the company designed its app to prompt users to set goals in onboarding, and implemented engaging feedback mechanisms for positive reinforcement.

User research can also help you decide how to deliver information to your users so that your product is frictionless to use. For example, what information is useful to see on the device vs on a smartphone? How does the wearable signal to the user that it needs to charge, or alert a user of a notification?

After launching the Quell® device, the team realized that the initial set up of the device was challenging to users. It was cumbersome to follow unfamiliar instructions while wrapping and calibrating the device on the leg. In response, they streamlined onboarding directly to the app to improve communication and replicate a process customers were used to.

For wearables that aim to be digital therapeutics, understanding your users is even more critical. While people may be intrigued by your offering, your challenge, according to McGillin, is getting them to believe that something digital can have the same effect as drugs." Companies should be deliberate in designing their product and educational materials to help customers grasp the mode of action and shift their long-held mental models.

Strong user research and human factors analyses can make sure your wearable is comfortable and usable. Image courtesy Neurometrix.

Ensuring Your Device is Truly Wearable

The unique challenge with making anything for the body is that humans move - a lot - and generally want to move freely. In McGillin's words, "A lot of the work we did with MANTA [on Quell 2.0] was thinking ‘How do we make this truly wearable?’ We looked at making the device smaller, lighter, and the band more comfortable."

To achieve this goal, our designers usually begin with a human factors and ergonomics analyses. This helps test the combination of device size, materials and body placement for comfort.

When making these hands-free electronics into clothing or accessories, companies can look to fashion and soft goods designers for inspiration. By drawing on specific construction methods, our designers can create a wearable that lays flush on the body with minimal pressure points. According to our VP of Design, Betsy Goodrich, "Smaller, thinner, rounded shapes work better as wearables - they are more stable on the body, blend well, and catch on things less."

We use our ergonomics analysis to user test different design concepts and prototypes. For example, when creating the Peerbridge wearable ECG monitor, we tested several usability factors with real users, from sensors to adhesives to skin preparation. Using different biocompatible adhesives and materials, we tested how well users could place the sensor patch and move comfortably with our concepts.

Given the wear and tear put on these devices, it’s vital to design for their full use-cycle, including cleaning. Designers must understand how and when a user cleans their wearable device without affecting its function. We often solve this particular challenge by creating a modular design that is highly usable and easier to clean.

Testing your device with different stakeholders ensures usability and generates buy-in.

Selecting and Sourcing the Right Materials

Wearable devices often consist of two detachable parts - the hardware device and a flexible band. A modular form factor allows users to swap out parts as needed. Product specialists can help you select the combination of materials that achieves the intended look, feel, and performance of your product.

Soft goods, like a wearable band, have more varying properties than hard, including stretch, stitch structure, and melting point. These can affect the comfort, performance, and cleaning requirements of a finished good. Flexible circuits, like those used by MIT startup BloomerTech, as well as e-textiles like the Loomia Electronic Layer, also give us the option of creating wearable clothing from only soft goods.

One factor that clients overlook when prototyping and going to production is the time needed for sourcing materials. Many are often made to order and can take up to 2-3 months to receive. Experienced product consultants can help you plan for and manage this part of your project timeline.

Designing for Durability

Wearables are subject to more moisture and temperature extremes than other devices. When conducting a hazards and risks analysis, our team recognizes that people wear devices while swimming, showering, or sweating. According to VP of Engineering Rich Miller, we have to pay close attention to our materials and sealing to protect sensors and connectors in our clients' hardware.

At MANTA, we not only create prototypes that embody your vision but also test these prototypes for performance. Using engineering analysis and testing, we help you guarantee quality and mitigate the risk of recalls.

As we mentioned earlier, the use of wearables 24/7 can put significant wear on your product. By engineering for durability, we extend the lifespan of the device and optimize its performance. These factors boost customer satisfaction and trust in your brand.

Assessing material samples can help determine which strikes the best balance of aesthetics and function.

Choosing Sensors Wisely

Generally, as the number of desired metrics increase, the number of wearable sensors or algorithms also increases. This can affect the size, amount of data stored on the device, and its power requirements.

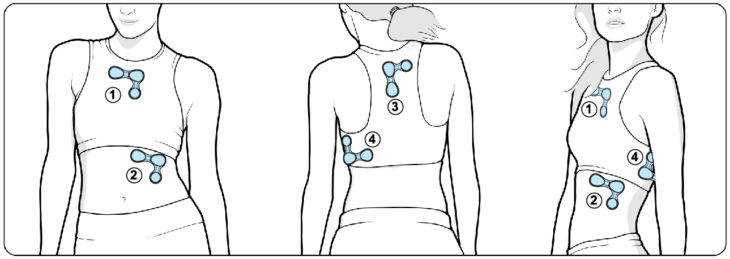

Accurate data collection from sensors also depends on their placement. To measure electrical activity from the heart with the Peerbridge Cor, for example, we had to place sensors in three locations.

When placing wearable sensors, we also have to consider how exposure to moisture, heat, and movement affect the signal. Sensors are also prone to drift, which can cause errors.

Flexible sensors embedded in soft goods, like MIT’s SensorNets, can reduce errors caused by movement or drift. Sensor design itself can also improve sensitivity. The Wyss Institute’s Soft-Fabric Sensors, use silicone embedded in conductive fabric to detect very fine movements with high sensitivity.

Sensor choice is not only dependent on the desired metric, but also on the method of measurement. There are many ways to capture any given biometric of interest. To measure heart rate, for example, we can rely on photoplethysmography, the technique used in the Apple Watch. Another method, capacitive sensing, measures the skin’s electrical impedance to measure heart rate.

These multi-factor decisions highlight the importance of integrated teams in making wearable devices. With in-house usability researchers, designers, and engineers, we can help you make the best choices for your product.

Extending Battery Life

Deploying wearable devices for extended periods is difficult for two reasons: memory capacity and battery life. Pairing wearables with phones allows the device to use the phone’s storage, but doesn’t solve the power problem. While optimizing sensors can help, transmitting data actually consumes the most energy.

Wearable devices rely on alkaline, nickel-metal hybrids, and lithium-ion batteries for power. Many batteries are bulky, with hard-edges, making them ill-suited for wearables. However, changing the size and shape of the device enclosure impacts battery and sensor size. Betsy and Rich both note that balancing these parameters are a primary challenge when developing wearables.

We can address this challenge through creative electrical engineering. Lithium ion polymer batteries are generally ideal because they are rechargeable and lightweight. They can also come in flexible, stretchable forms that are particularly suitable for soft goods like wearable clothing.

New technologies like miniature electronics also enable us to make smaller, lighter wearables without sacrificing accuracy. With our work with Neurometrix, Betsy notes that, "redesigning the electronics reduced the battery size in the new Quell design by half, greatly improving fit and stability on the body."

Another innovative approach to powering wearable technology is through energy harvesting. This technique can draw on body heat, as in the case of the Matrix PowerWatch, or rely on triboelectricity. These technology innovations can help you deliver a cutting-edge product that stands out in this growing market.

Your choice of sensors and their placement are critical to determining how well your device performs.

Going from Manufacturing to Market

Different manufacturers usually specialize in different processes. The unique combination of components in wearables make it hard to find one manufacturer who can do it all. Asking a manufacturer used to producing molded parts to also adopt advanced garment construction techniques is unwise. These processes need both the right machinery, skills, and experience to assure the quality of your product.

Wearable medical devices in particular have to pass more stringent regulatory vetting. A manufacturer unfamiliar with med devices might not consider finding medical-grade materials. When creating wearable technology for healthcare, we work with trusted ISO 13485-certified manufacturers.

Given these complexities, clients often struggle to communicate what they need from manufacturers. Having product consultants with a strong network can help you find manufacturers with the right production strengths to bring your vision to market.

Packaging aligned with your brand can help you stand out in a crowded market

Prototype Your Wearable With Us

Developing comfortable, high-performing wearables requires a multi-disciplinary approach and strong partnerships. This is especially true for wearable medical devices that need to adhere to FDA guidance. With a team that can assess your design and technology, your device can deliver unparalleled value to your customers.

Do you have a great idea for wearable technology? Our industrial designers and engineers can help you evaluate concepts and make prototypes for testing. Start now.

[…] (37)What Should You Know Before Making Wearable Devices? […]

[…] (43)What Should You Know Before Making Wearable Devices? […]

[…] (52)What Should You Know Before Making Wearable Devices? […]