Invest Early in Product Architecture

Investing time to define product architecture early in the product development process is critical to success. A comprehensive development plan, expertise, experienced team, fiscal oversight, and informed decision-making are essential to controlling costs during successful product development programs.

Product architecture refers to a product's essential functional elements and how they interact with one another. Identifying and selecting the optimum product architecture for a new product is critical to success or failure. Designers need to consider various factors, including ergonomics/usability, functionality/performance, manufacturability, regulatory compliance, intellectual property considerations, and corporate business/marketing strategies.

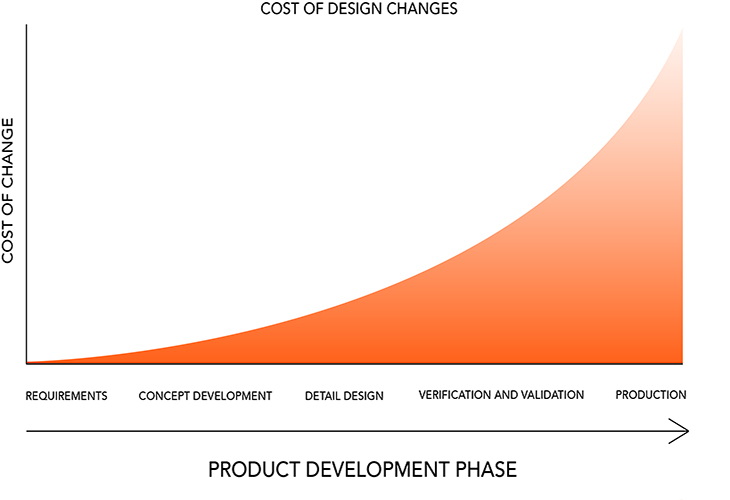

Project managers often attribute development cost overruns to design architecture changes further down the development path. Downstream design changes have a proportionally increasing development cost and schedule impact when implemented further into the development cycle.

Right the First Time

It isn't easy to get it right the first time, and it takes time and a structured process. Early-stage exploration, design iterations and evaluations are essential to allow the optimum product architecture to emerge from the process. Incorrectly choosing a design architecture early in development will guarantee costly design changes later.

Manta's Phase 0 development process is structured to explore multiple design solutions in parallel. Our research informs design concepts that can be critiqued by users or evaluated by technical experts. This approach has multiple benefits:

- Early-stage concepts require low investment

- Evaluating multiple design solutions expose failures and uncover opportunities

- Design failures provide high-value learning

- Informed experience facilitates good design decisions

The following case studies illustrate the value of an initial product architecture effort and its significant impact on program success.

The cost of design changes increases over time.

Usability Driven Product Architecture

The LAVA Chairside Oral Scanner (COS) (https://mantadesign.com/work-dental-imaging/) is a dental imaging system that uses optical scanning technology and high-speed data processing algorithms to create a real-time 3D point-cloud database of a dental patient's tooth geometry. This innovative system solves the challenges experienced with traditional dental mapping by providing dentists and patients with highly accurate real-time digital impressions, reducing fitting time, and eliminating costly remakes of crowns, bridges, and abutments.

At the project start, the initial LAVA COS specification defined the device as a countertop system. Manta conducted usability research (https://mantadesign.com/boston-human-design-factors-usability-ux-ui/) early in the product development cycle, which included dental office site visits and interviews with target users, including dentists and hygienists. The study clarified LAVA workflows and use scenarios that highlighted three key findings:

- The is minimal available counter space in most dental suites.

- The Oral Scanning process requires close interaction with the LAVA's touch screen display controls.

- Device Transportability between dental treatment suites is critical.

These usability research findings revealed that a cart-based design configuration, not a countertop-based system, was the optimum product architecture for the LAVA COS System.

The resulting cart-based product design was a great business success and led to the acquisition of the original start-up client Brontes Technology by 3M ESPE. In addition, the LAVA COS won the BusinessWeek IDEA Best Product Design of the Year Award.

Brontes oral scanner.

Manufacturability Driven Product Architecture

The intubation procedure involves the placement of an endotracheal tube into a patient's upper airway for artificial ventilation (https://www.sciencedirect.com/topics/nursing-and-health-professions/laryngoscope-blade). The tube placement maneuver is often conducted in emergencies and can be challenging even for trained healthcare workers due to space and visibility constraints. Metal laryngoscope blades help guide the tube into position but can cause damage to a patient's teeth and soft tissue. In addition, traditional laryngoscope blades do not allow the user to visualize the upper airway to facilitate the correct placement of the endotracheal tube.

The King Vision Video Laryngoscope (https://mantadesign.com/work-laryngoscope-device/) addresses these issues by incorporating an imaging sensor, OLED video display, and plastic blade. These design features allow for clear visualization of the patient's upper airway, helping to ensure correct placement of the endotracheal tube while minimizing patient injury.

The business and patient cross-contamination requirements for the Vision Video Laryngoscope called for a "razor/razor blade" product configuration whereby the blades are single-use disposables. Accordingly, a product architecture investigation was undertaken by Manta at the start of the development program to determine the optimum partitioning of the new video laryngoscope system reusable and disposable elements. Critical decision-making criteria included blade manufacturing cost and complexity, overall device size and use ergonomics, and intellectual property strategies to prevent knock-offs/competitor blades from being used with the system.

Manta's product architecture development activities included an upfront manufacturing investigation focused on minimizing the overall cost of the blades. Low cost/high-resolution imaging sensors were identified from the cell phone camera market, which allowed the imaging sensor and illuminating LED to be positioned at the distal tip of the device. This allowed for optimum device vision performance while eliminating the need for complex/costly fiber optic components to be incorporated into the blade. A moldability investigation was performed on the blade enclosures to verify that their complex curved geometry/parting lines could be manufactured cost-effectively and reliably. An assembly investigation was also conducted to identify the optimum method of joining the enclosures to achieve a robust and fluid-tight bond.

For the "razor" component of the system, the OLED video display, control electronics, and batteries were incorporated into the reusable upper portion of the device. In addition, a proprietary mechanical/electrical interconnection scheme between the reusable and disposable components was developed to obtain patent protection to block potential knock-off/competitor blades from being used with the system.

The above product architecture work led to a game-changing new device design that revolutionized the laryngoscope blade market. In addition, the associated manufacturing investigation resulted in a single-use, disposable blade design that met the target cost and ease of assembly requirements, making the product a huge business success for King Systems.

King Vision Video Laryngoscope.

Environment Driven Product Architecture

The Peerbridge Cor™ Wearable ECG sensor (https://mantadesign.com/work-wearable-sensor/) is a small, wearable ECG monitor that provides a continuous, multi-channel recording in addition to patient-activated event data transmission for up to 7 days. The Peerbridge Cor™ Wearable ECG sensor continuously records 2-channel, 3-lead ECG data and provides improved patient compliance via its minimal size and simplicity of operation.

Given the wearable nature of the product and the target 7-day monitoring period, the device needed to be sealed against moisture ingress from patient cleaning, bathing, and sweating. At the same time, human factors and comfort were of paramount importance, as were the ECG signal acquisition, battery life, and manufacturability requirements

In order to determine the optimum environmental sealing strategy for the device, Manta undertook a product architecture investigation that included parallel engineering exploration, usability research, and manufacturing strategy development. A wide variety of electronic designs and corresponding sealing strategies were developed and tested. Based on the results of this early-stage investigation work, the Cor's electronics were designed using rigid-flex circuitry. The three rigid sections of the electronics are encapsulated within thin plastic injection molded enclosures that provide both moisture and physical protection. Flexible over-molding is then applied over the flex portion of the circuitry to encapsulate them and to seal the openings where the flex circuitry enters the plastic housings. This design configuration provides the required environmental sealing to protect the electronic circuitry while still allowing for the device to conform to a wide range of patient chest anatomies for comfort. In addition, multiple batteries are located throughout the system to minimize the overall size and weight of the individually molded enclosures while still achieving the target battery life.

The resulting product design received FDA clearance and offers a significant advantage in the signal acquisition, wear-time, and user comfort over existing competitive products.

The Peerbridge Cor™ Wearable ECG sensor.

Conclusion: The Importance of Product Architecture

As outlined in the above examples and countless others, determining the optimum product architecture can be critical to a product's overall success. Product architecture evaluation should be performed early in the development cycle and should consider the functional, ergonomic, manufacturing, and business/marketing requirements for the product.

Successful product development plans should include product architecture research, conceptualization, technology feasibility, and design evaluations early in the development cycle. This approach ensures that go-forward development focuses on the "truly best" product architecture. Failing to do so risks a time-consuming and expensive redesign later in the development process or to a poor customer/market response.

Manta Can Help

Our experienced team of researchers, designers, and engineers can help you determine the optimal Product Architecture for your new product. Get started now. [Link to Manta Contact Page]

Let's get started now.